After your product is complete and you are prepared to begin selling it, there is one more thing to consider: how will you send it? It might be challenging to determine which box style and size is best for your products when there are so many options available.

You might easily become agitated when faced with seemingly endless choices, such as rigid boxes vs corrugated boxes, or shipping boxes vs. mailer boxes. Fortunately, you may take some steps to ensure that your packaging and delivery procedure is simple and flawless.

We’ve provided you with an easy-to-follow, thorough guide that will assist you in getting the right box dimensions, figuring out a box’s volume, and remembering a key aspect that will ensure you get the most precise measurements.

So, stay tuned!

The Three Main Dimensions Of A Packaging Box

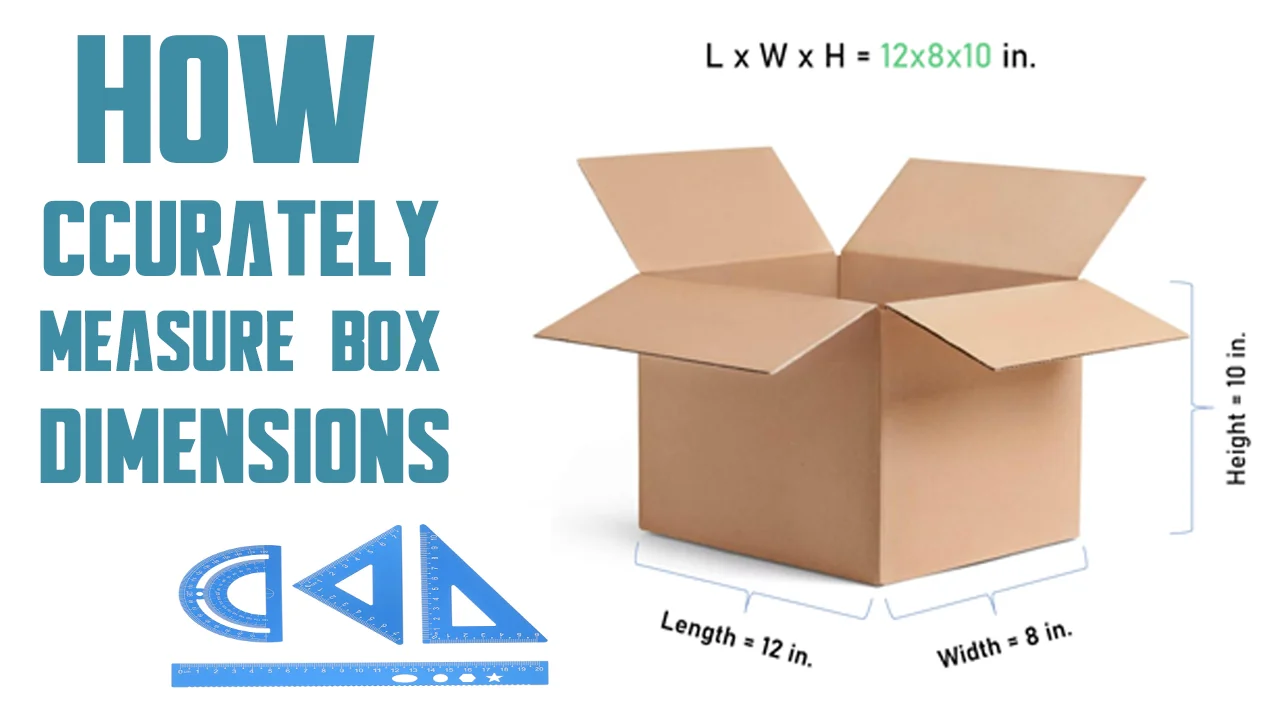

The more precise the dimensions of a box, the more excellent your packaging will be. The three metrics length, width, and height are essentially used to calculate a box’s dimensions.

Longest dimension- Length (L): The longest dimension of the box, as seen from its top, is referred to as its length. To begin, measure the length in either centimeters (cm) or inches.

Horizontal dimension- Width (W): From a top-down perspective, the box’s width is its horizontal portion. An item’s width determines its available space, so use it wisely.

Top to bottom portion- Height (H): After taking measurements of the other dimensions, you must examine the side perpendicular to the width and length. Take your measurements carefully, starting at the bottom and working your way up.

You now know the measurements of length, width, and height. These measurements need to be exact to provide the perfect box for the item you are selling. It is necessary to figure out the correct dimensions for each of your boxes, whether they are ornamental objects boxes, food boxes, or hemp oil boxes.

We also suggest catching assistance and completing the project if you feel you are not measuring it correctly. The goal is to avoid compromising on box measurements.

Important Tools For Determining Custom Box Dimensions.

Measuring your boxes does not require an array of instruments. To get going, you’ll need these:

- A measuring tape.

- A straight edge or ruler.

- A pen and sheet of paper for writing down your measurements.

How To Calculate The Box Dimension?

Step#01: First and foremost, place the item on a level surface and measure its longest side i.e. length (L).

Step#02: Secondly, rotate the item now, then measure its wider side i.e. width (W).

Step#03: Finally, take a top-to-bottom measurement of the product i.e. height (H).

Now use the formula to find the dimension of the box.

The formula to calculate the dimension of a box is very simple. Here is the formula

Length*Width*Height or L*W*H

Your item’s packaging supplier will also create your packaging boxes using this formula and ordering of measurement.

Why Interior Box Measurements Are Necessary?

To discover how to inevitably arrange your items in their respective boxes if you have hired a packaging provider to create your boxes, you should first determine the inside dimensions of the necessary packaging box. It is vital to understand the inner measurements of the packaging boxes.

Taking only the external dimensions measures is one common mistake people make when calculating a box’s size. In particular, when working with heavier materials like corrugated cardboard, determining box measurements in this manner fails to account for the thickness of the box.

Corrugated cardboard has a double-walled construction and can contribute a significant amount of extra mass. Therefore taking interior measures is important and it provides a flawless fit for the item inside.

If you use only external dimensions, you face the danger of having boxes that are far too small, causing items to either not fit at all or fit snugly up against the edge of the box. For this reason, the majority of businesses that offer product packaging ask for the inside rather than the outside box dimensions.

How To Find Out A Box’s Volume.

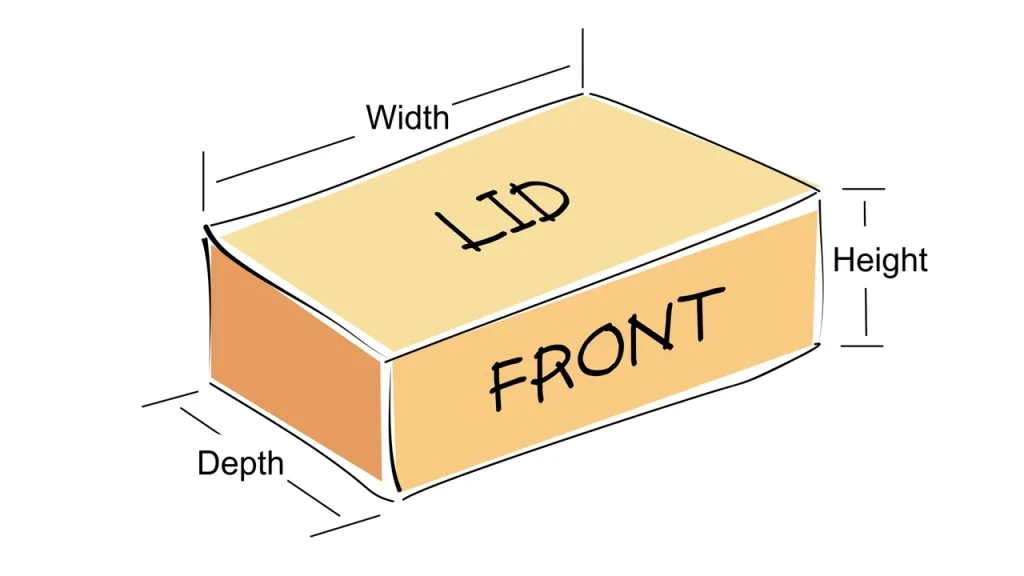

To find out how comfortably your goods will fit within the packaging and to get a better grasp of your transport, storage, and delivery procedures, measure the length, breadth/width, and depth of your box. Then, calculate the volume of a box using these measurements.

Don’t skimp on this step—volume is essential for material optimization, minimizing costs, and packaging structural design. Simply multiply all the dimensions using this formula:

Volume=Length* Width*Depth

Notably, however, it is technically optional to understand which measurement matches which dimension when using the above formula to determine a box’s volume. Nevertheless, it’s simply a good habit to have in mind. We strongly advise being aware of this information to prevent confusion or errors in the future.

However, if you’re not the best at arithmetic and want a tool to help streamline this process, you may get precise volumetric measurements for your container by using this handy calculator.

Selecting The Appropriate Box Size For Your Items Dimensions.

There are a few considerations you should make while selecting the appropriate size box for the task at hand.

The following advice will help you select the appropriate size box:

What dimensions does your product have?

To ensure you have the precise size you need, check your item before you go box purchasing.

What quantity of boxes do you require?

Once you are aware of the product’s measurements, you may begin to estimate the number of boxes you will require. Remember that the amount you require will vary based on the kind of job you are working on.

How are you going to use the box?

Do you plan to ship it or keep it for storage purposes? Select a box that is intended for shipping if you intend to transport your products. Additionally, if you want to store your creation, pick a box that is strong and won’t break under the load of the item.

How much weight does your product have?

This needs to be taken into account because not all boxes are designed to accommodate hefty objects. Therefore, before buying, make sure you verify the container’s weight limitation.

What’s your spending limit?

Selecting the ideal packaging technique for your items requires a thoughtful assessment of your available budget. Be concerned about the price as much as the quality and appearance.

Though you shouldn’t sacrifice quality or other important factors, try to discover a top packaging company at a cheaper price.

Wrap It Up!

Mastering the skill of measuring custom box sizes for dimensions and box types requires both accuracy and innovation. Precise measurements guarantee a precise fit for your goods, while the ideal style elevates your company’s image and improves client satisfaction.

You’re now prepared to handle all sorts of custom packaging boxes due to this article. Together with “Tycoon Packaging”, let’s confidently package those goods!

To minimize wasteful material use and lessen the environmental effect of shipping, have boxes made specifically to meet your items’ size. Furthermore, you can minimize the need for extra packing material by selecting the appropriate box size and packaging supplies to guarantee that your things are safeguarded during transport.

This concludes our guide on precisely measuring and writing down a box’s dimensions. To prevent expensive errors, always take your time and verify your measurements.

Cheers to your happy shipping!