Precise box measurements are vital for ensuring safe shipping and maximum product protection. The right measurements help you optimize material usage, reduce shipping costs, and keep the encased product protected. This practical guide gives the right answer to “How to measure box dimensions”.

There are various things to consider. Let’s dive into detail to know everything related to box dimensions.

What To Know Before Measuring Box Dimensions?

Before the box dimensions measurement, you have to know something. Take a look at some of the fowling aspects:

- Use the right tool for measuring the box dimensions.

- Place the packaging on a flat surface to ensure accurate measurements.

- Record box dimensions in the standard order of Length x Width x Height.

- Employ a consistent unit of measurement, such as inches or centimeters.

What Tools Are Used To Measure Accurate Box Size?

For measuring the box dimensions, you need to have a measuring tool. Here are some of the measuring tools that are used to take accurate box measurements:

- Ruler

- Measuring Tape

- Yardstick

- Digital Caliper

- Dimensional Scanner

- Laser Measuring Device

- Mobile App with AR Technology

- String

How To Measure Box Dimensions?

Whether you are shipping products or simply trying to organize storage, understanding how to measure box dimensions accurately is important. To measure packaging dimensions, the right approaches must be used to get precise measurements and help you select the right box size.

In this guide, we will walk you through the simple steps to measure dimensions.

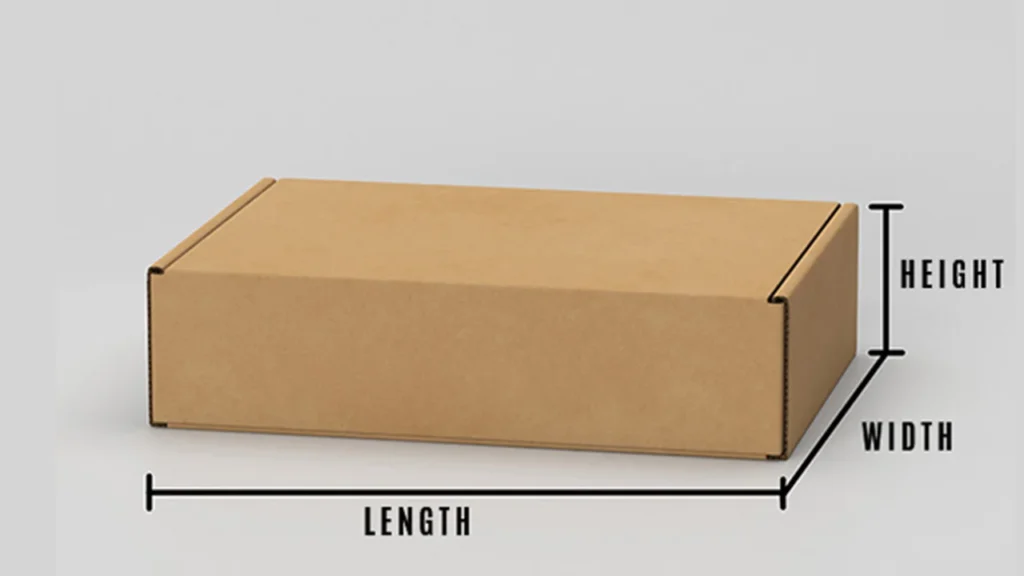

Measure Box Length

The first step is to measure the longest side of the packaging. Identify this side and then take the measuring tool along the edge of the packaging.

Measure Box Width

Now measure the side perpendicular to the length, which is the shorter side. Position the measuring tool at the top of the box and measure across from one end to the other.

Measure Box Height

To measure the height, take the distance from the top of the box to the bottom. Place the tools to measure the vertical dimension.

Calculate Box Volume

Measure box volume by multiplying the length, width, and height to determine how well products will fit inside. The formula for calculating volume in cubic inches is given below: Volume = Length × Width × Height

Calculate Girth (if required)

Calculate the girth by using the formula (Length × Width × Height (L × W × H)). This helps determine the total circumference of the box around its perimeter.

Record Box Measurements

Record the measurements in the standard order of Length × Width × Height (L × W × H) after taking all the measurements.

What Are Some Of The Common Mistakes When Measuring Box Dimensions?

People try to measure the box dimensions with complete precision. But they take the incorrect measurements due to some common mistakes. Here are some of the following mistakes when measuring the box dimensions accurately:

Place The Box Incorrectly While Measuring

People place the box incorrectly while measuring, causing inaccurate dimensions of the packaging. To avoid such mistakes, always position the box on a flat surface to ensure correct measurements such as length, width, and height.

Measuring Only The External Dimensions

The individuals measure the external dimensions of the packaging, which leads to some issues in shipping and packaging the products. The external box dimensions are important for shipping calculations. But the internal box dimensions allow the product fit in properly.

The thickness of the box wall, especially in cardboard material, reduces interior space, making accurate internal measurements essential.

Using Inconsistent Units

The use of inconsistent units can lead to measurement errors and calculation issues. That is why we use the same unit, such as inches or centimeters, for all box dimensions. Never use different units for measuring all the calculations; this can be confusing.

Always use the same unit for measuring box dimensions to avoid incorrect volume calculations and sizing mismatches, impacting shipping and packaging accuracy.

Not Including Space For Padding

People do not include the space for padding or protection materials such as foam, bubble wrap, or inserts while measuring box dimensions. This can lead to incorrect measurements, increasing the risk of damage during storage and shipping. Therefore, always account for padding and protection materials to ensure a secure fit.

These are some of the most common mistakes to ensure that your box will be appropriately sized for the products, reducing the risk of product damage or storage issues.

Why is Precise Box Measurement Important for Product Packaging?

There are a wide variety of benefits when it comes to precise box measurement. Take a look at some of the following benefits that are common for everyone:

Product Protection

The right measurements of the packaging ensure a perfect fit for the packed product, minimizing the chances of the product moving. A well-fitted box prevents impacts, vibrations, or crushing, reducing the risk of damage while handling, displaying, storing, and shipping.

Branding & Aesthetics

The accurate measurements of the packaging enhance the aesthetics of the packed products. It also helps your product and brand stand out on the shelves from others. The right-sized packaging gives a perfect fit, preventing product damage and creating visually appealing packaging.

Material Optimization

The appropriate dimensions of the packaging minimize the use of excess packaging materials. This approach supports sustainability goals and reduces environmental impact. That is why the right size of the packaging optimizes material, reducing the overall production cost.

Cost Savings

The right size of the packaging lowers the overall cost. Don’t know how? Accurate size of the packaging lowers the material use, production expenses, and shipping charges. Effectively sized packaging optimizes warehouse storage, reduces storage costs, and improves logistics efficiency.

A Table That Shows An Overview Of How To Measure Box Dimensions

This table helps you give an overview of measuring the box dimensions in the glimpse.

| Dimension | What It Measures | Example (inches) | Used For |

| Length (L) | The longest side of the box | 16″ | Product fit, shipping labels |

| Width (W) | The shorter side of the base | 12″ | Product arrangement, box strength |

| Height (H) | Vertical distance from base to top | 10″ | Shipping cost, shelf fit |

| Outer Dimensions | External box size with flaps | 16″ × 12″ × 10″ | Shipping quotes, warehouse logistics |

| Inner Dimensions | Usable space inside the box | 15.5″ × 11.5″ × 9.5″ | Product packaging, internal cushioning |

| Total Size | Combined measurement (L + W + H) | 38″ | Carrier surcharge thresholds |

| Volumetric Weight | Dimensional shipping weight | ~13.8 lbs | FedEx, UPS, DHL, international shipping |

| Girth + Length | Parcel measurement for couriers | G+L = 64″ | USPS shipping guidelines |

Where To Get The Packaging with The Suitable Dimensions?

Tycoon Packaging specializes in manufacturing the packaging of any type in any dimension using our endless customization options and modern die-cutting & printing techniques. We use top-quality materials, unique layouts, vibrant printing, remarkable finishes, and unique add-ons to craft these boxes for effective branding.

We create these boxes tailored to your needs with complete precision at wholesale rates. So, what are you waiting for? Feel free to reach us and discuss your packaging needs.

Final Verdict On How To Measure The Box Dimensions

To measure the dimensions of the box with complete precision, read the complete guide. This guide covers everything you need to know in detail. Start by preparing the box on a flat surface. Measure the length, width, and height.

Find volume and calculate the girth. Be sure to record the measurements and account for padding. Know what mistakes to avoid and why the right dimensions are important for the encased product.

FREQUENTLY ASKED QUESTIONS

Q: How do you calculate the size of a box?

To calculate the sizes of the packaging, measure its length, width, and height. For example, if a box is 10 inches long, five inches wide, and four inches high, then its volume would be 10 x 5 x 4, which equals 200 cubic inches.

Q: Is there an app to measure a box?

Of course! There are a few apps available to measure the size of the packaging. For example, the iPhone app “Measure Kit” provides a suite of advanced tools for measuring 3D objects. Other apps, such as “AR Measure”, use augmented reality and your device’s camera to measure objects in real time.

Q: Can I measure a package without a scale?

Absolutely! You can measure the size of the packaging without a scale. But it can lead to inaccurate measurements and additional charges if you calculate the box dimensions wrong. We strongly recommend using a scale.

Q: How to calculate the dimensions of the packaging?

Length, width, height, and girth are the dimensions of the packaging. Therefore, use a measuring tape to measure the item’s length, width, or height to determine dimensions. To determine girth, add width to height and multiply by two.

Q: Should I round up the box dimensions for shipping?

Of course! Most carriers recommend rounding each dimension up to the nearest whole inch to ensure accurate billing and avoid delays.