Shipping is needed to transport food, electronics, artwork, or other items from one place to another. Therefore, packaging is needed to ship them in a protected way. This is where minimum box thickness for shipping art comes into play.

When designing cardboard packaging for your brand, you have a number of choices. Material thickness is the most important aspect you must consider when creating packaging. In this guide, you will explore cardboard thickness, types of packaging, and other considerations you need to know in detail.

Table of Contents

1. Why Box Thickness Matters for Art Shipping

2. Recommended Minimum Box Thickness for Shipping Art

3. Understanding Cardboard Thickness: mm and GSM

4. Types of Packaging

– Corrugated Boxes

– Cardboard Boxes and Their Role

5. Choosing the Best Packaging

6. Final Thoughts

Why Does Box Thickness Matter?

Usually, all the cardboard boxes look similar at the first glimpse. However, they have different cardboard thicknesses to keep the products protected from damage during storage and transit. Here’s why:

- It keeps packed products protected

- It helps to withstand the rigors of shipping

- It minimizes the shipping costs

- It also provides a surface for the best printing

Right Material Thickness Protects The Packaged Products

Thickness of the material determines how protective packaging is for various items. Protection is particularly important for delicate, fragile, and breakable products that require extra care and safety during storage and transit.

Protecting valuable products from external impacts during shipping needs thicker cardboard that helps you prevent them.

Survive The Rigors Of Handling & Shipping

Shipping is a daunted task for various businesses due to the loss of products during shipping. As boxes stack over each other, they are in really bad shape. Therefore, it is necessary to have boxes that are durable and sturdy to not only ship goods but also withstand the rigors of shipping.

Material thickness is one of the most important factors in the survival the damages during shipping. So, make sure these boxes are designed to survive these rigors of handling and transportation.

Reduce The Cost Of Shipping

Right thickness is crucial for protection and shipping. But it is also important for minimizing the shipping cost. Don’t know how thickness influences shipping cost? Packaging manufactured from thicker cardboard material will be heavy which results in higher costs for shipping.

But at the same time, these boxes with more thickness also protect your product during transit. This means your products get no or negligible damages which reduces to return and replace orders.

Vibrant Printing To Promote

People avoid dull and bland packaging these days and avail the golden opportunity to promote their brand. Therefore, all businesses and brands utilize their boxes and make them the window of their business and brand. These boxes offer abundant space for printing brand emblems, names, slogans, and product details.

These elements inform the potential customers who you are. However, cardboard thickness can influence the results of printing. So, consider the thickness that allows HD printing on the packaging.

Recommended Minimum Box Thickness for Shipping Art

Shipping needs vary from product to product. For some products, the minimum box thickness for shipping art should be appropriate but for others, it does not. Therefore, knowing the right cardboard thickness is essential to provide enough strength without adding excessive weight.

There are various methods for measuring the thickness of cardboard such as grams per square meter (GSM), the point system (PT), flute type, and board style. This blog discusses each method to help you select the right thickness of packaging for your packed products:

Cardboard Thickness GSM

GSM stands for grams per square meter which refers to measuring the weight, length, and width of packaging materials such as cardboard. It is one of the most accurate and precise methods of measuring the material thickness. However, GMS can be difficult to convert this unit into any other unit that you can actually know and understand.

Here we will explore some thicknesses for different types of products. It will help you to get a better understanding of measuring cardboard thickness:

- 35 to 55 GSM is often used for newspapers

- 90 to 100 GSM is often used for printer paper

- 120 to 140 GSM is often used for posters

- 210 to 300 GSM is often used for brochures

- 350 to 400 GSM is often used for packaging

So, if you are looking for thick and strong cardboard for packaging, choose a thickness above 350 GSM.

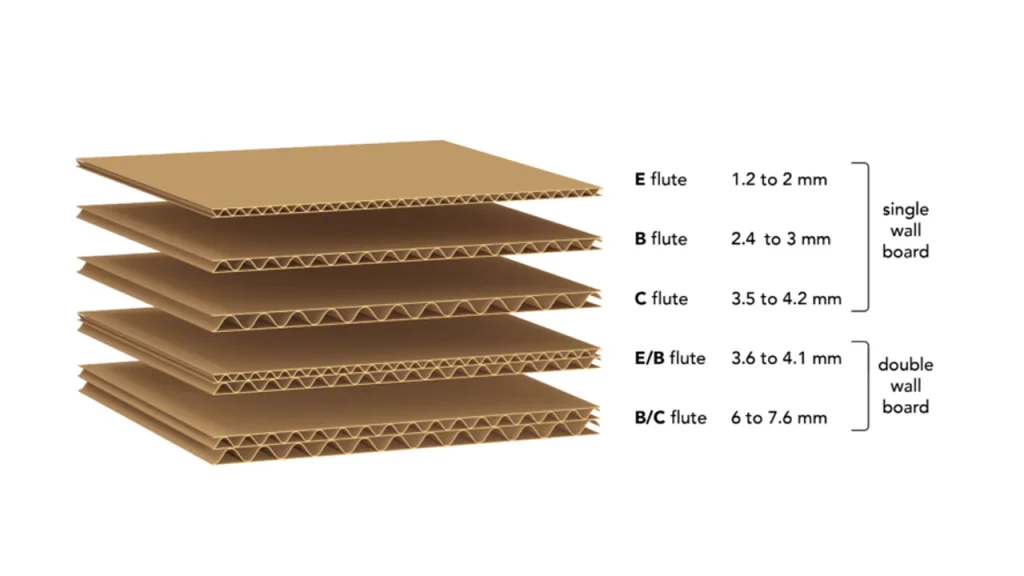

Corrugated Cardboard Flute Type

It is another way of measuring cardboard thickness. The corrugated flute refers to the wavy sheets of paper found between the cardboard liners in the corrugated cardboard boxes. The design of these flutes leads to boxes that are more protective for the products.

Various flute sizes are available to choose from such as minuscule and substantial. Flute sizes are named based on the order in which they were invented. Available cardboard thickness mm and their name are given below:

- A flute is 5 mm or 1/4”

- B flute is 3 mm or 1/8” (0.125”)

- C flute is 4 mm or 11/64”

- D flute is 2 mm or (.085”)

- F flute is 0.6 mm or 1/32”

C flute is popular and versatile to safeguard a wide range of different products during shipping and storage.

Material Thickness PT

The PT is also used to measure the thickness of material, including the corrugated material that is used for cardboard packaging. Each “point” in this unit system represents 1/1000 of an inch. There are various options available in the market ranging from 8pt to 16pt.

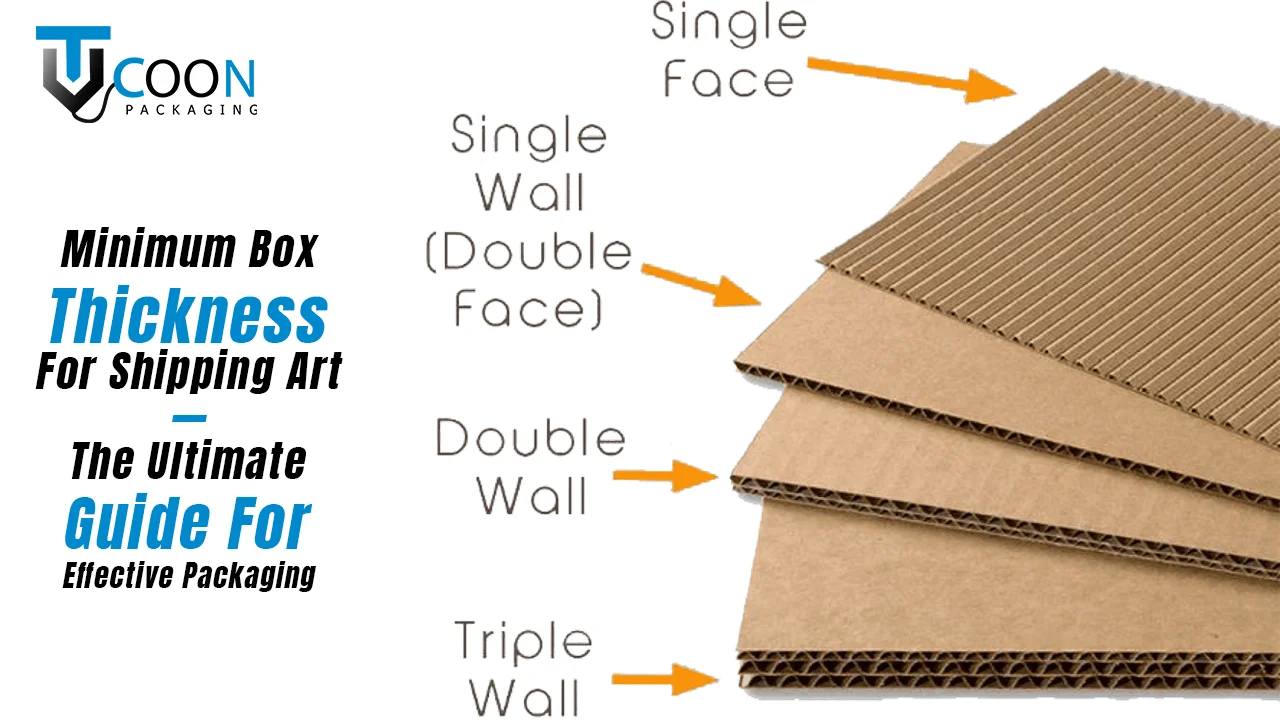

Corrugated Board Style

The corrugated style determines the thickness of the cardboard. This refers to the perfect blend of various flutes and liners in corrugated cardboard boxes. These boxes are single wallboards, featuring a single fluted layer between two liners. However, single-face boards, double wallboards, and triple wallboards are also available.

Single face boards (3-4 mm): A single piece of liner paired with one piece of fluted paper.

Double wall boards (6-7mm): Three pieces of liner surrounding two pieces of fluted paper.

Triple wall boards (10-12mm): Four pieces of liner surrounding three pieces of fluted paper.

Types of Boxes That Can Be Mad From Cardboard Material

Selecting the right type of packaging is important for safe shipping. Therefore, you need to choose the options that best suit your product needs. Most popular choices of boxes for shipping products are:

Corrugated Boxes

These boxes keep the product protected from the shock and impacts of shipping and provide cushioning due to its fluted layers. These boxes are perfect for shipping fragile and delicate products for optimal protection.

Cardboard Boxes

These boxes are perfect for small and lighter items. These boxes are paired with interior padding to protect the products during handling, loading, and shipping products.

Custom Food Boxes

These boxes are primarily designed to hold and protect various food items during transportation. These boxes are moist-resistant, branded, and customizable.

Paper Tube Packaging

Paper tube packaging is the perfect way to pack, protect, present, and ship elongated products such as prints, maps, or posters. These tubes with customizable thicknesses provide a compact solution for shipping rolled, elongated, or lengthy products.

Choosing the Best Packaging for Your Products

There are various important factors when it comes to choosing the right packaging for your products. These factors help you have a better understanding of why minimum box thickness for shipping art matters. They also guide you to choose the best packaging for your products. Here are a few key points to consider:

Consider Product Type

Are your products fragile or heavy and need extra care and safety? Product type is crucial when it comes to choosing the packaging for your brand.

Consider Size & Weight

If you want to package heavy products, you need sturdy and robust packaging boxes. Are your boxes large enough to fit your products? The size of your products also matters the most to pack products of different sizes.

Destination Distance & Conditions

Shipping is an important part of choosing the appropriate packaging for your brand. If you are using a local delivery service, then you might not need durable packaging. But, if you are using a third party to pick, pack, and ship your products, then you need robust packaging for products.

Keeping all this in mind, you should select the packaging for the products.

Final Thoughts — Minimum Box Thickness For Shipping Art

Selecting the right thickness for packaging boxes is an art to protect your products and keep them in pristine condition. By understanding the thickness of cardboard in mm and GSM you will be able to choose the right material thickness. The benefits of custom packaging options mentioned in the blog will also help you make informed choices for the products during transit.

FREQUENTLY ASKED QUESTIONS

How many mm thick is cardboard?

Cardboard thickness varies from the ‘A’ flute, which is 3/16″ (4.8mm) thick to E-flute which is 1/16″ (1.6mm) thick. Choose the appropriate one for your product needs.

How thick should cardboard be?

It depends on various factors such as product type, size, weight, and shipping methods. Choose the right thickness from A to E flutes depending on the nature of the product and the shipping method.

How thick is a standard shipping box?

The standard thickness of these boxes is 1/8″. These shipping boxes ensure the product reaches its destination in perfect condition. Looking for a specific thickness? Just share the material thickness with us. We will manufacture custom shipping boxes according to your needs.

How thick is a boxboard?

Boxboard boxes are made from layers of paper pulp typically around 600 microns in thickness. Folding box board is a lighter yet strong material with impressive qualities such as foldability.

What is the best packaging for shipping art prints?

Mailing tube is a common way to pack, protect, present, and ship larger prints, posters, or artworks that can be rolled without any damage.

What kind of boxes are acceptable for shipping?

These boxes should have plenty of space for products and can hold the weight of the product. Choose the one that offers both during shipping.

What does a 200 lb test mean for boxes?

These boxes are made with heavier paper and have 60% greater bursting strength than 32 ECT boxes. It means less damage during shipping.

What is the GSM of cardboard?

The higher number of GSM means heavier cardboard material. The market is flooded with options ranging from 200GSM to 1000GSM to ensure the higher quality packaging boxes fulfill all of your packaging needs.

How thick is 400 GSM cardboard?

400gsm = 315 to 460mics.

What is the standard thickness of cardboard?

The standard thickness of cardboard may vary depending on its intended use. Single wall cardboard (3-4 mm), double wall cardboard (6-7mm), and triple wall cardboard (10-12mm) are popular options for shipping products.

What GSM is good for boxes?

300–400 GSM, this range is best for packaging boxes.